Feature

01

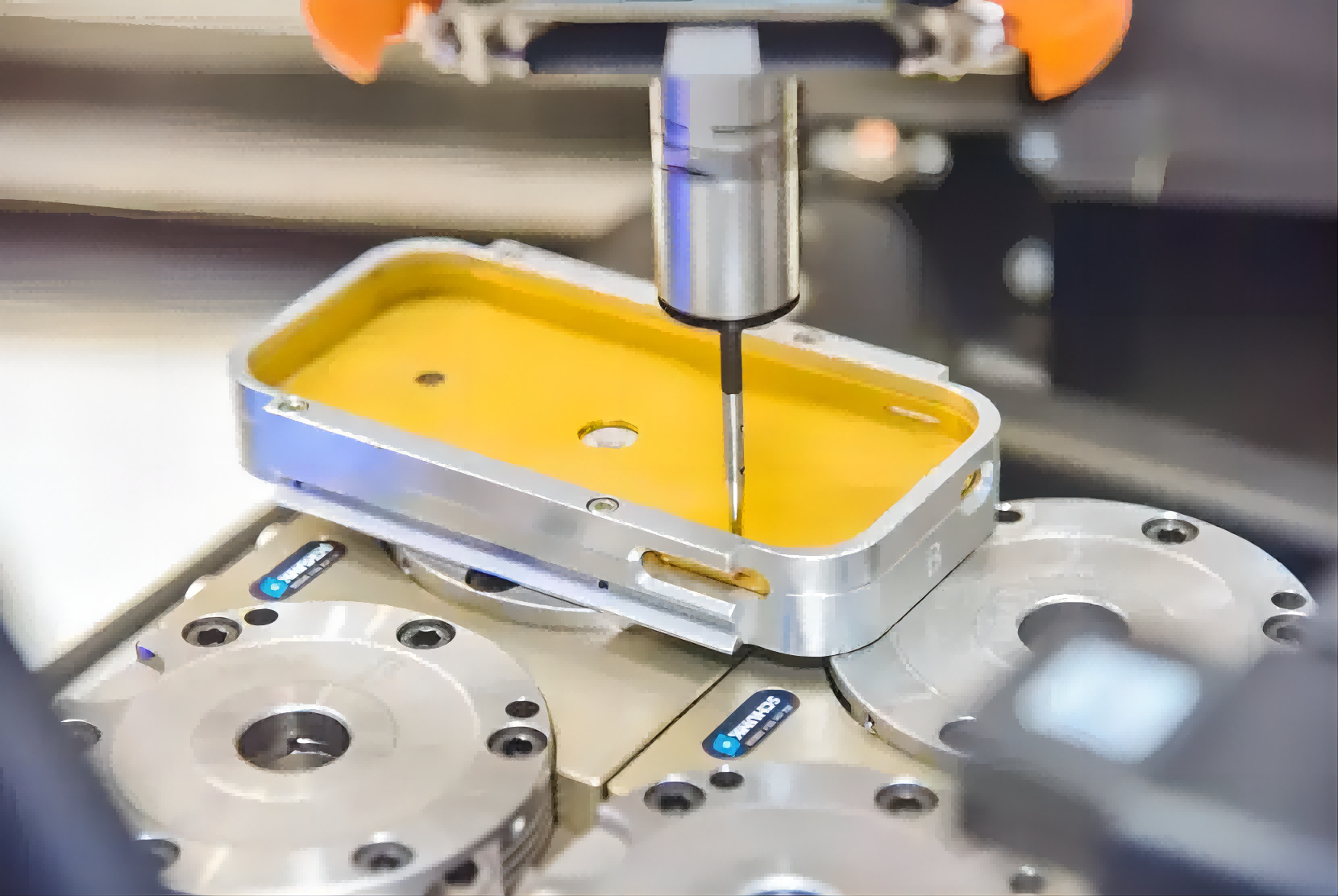

All three axes use pre-tensioned rods to effectively suppress thermal elongation of the three axes, with better precision and stability.

02

The Z-axis adopts pre-tensioning structure, which can not only suppress the thermal elongation of the lead screw but also offset the thermal elongation of the spindle, so as to further improve the accuracy and stability of the Z-axis.capabilities.

03

The spindle bearing adopts imported high-precision ceramic ball bearings, which have high spindle precision and small temperature rise.

Specifications

| Item | Project | Unit | Specifications |

|---|---|---|---|

| Travel | X axis travel | mm | 800 |

| Y axis travel | mm | 500 | |

| Z axis travel | mm | 450 | |

| Distance from spindle nose to worktable | mm | 180-630 | |

| Distance from spindle center to column | mm | 411 | |

| Workbench | Workbench size | mm | 1100x500 |

| T-slot(sizexslot no.xspace) | mm | 14x5x80 | |

| Maximum load of workbench | kg | 400 | |

| Spindle | Speed | rpm | 12000 |

| Spindle taper | # | BT30 | |

| Transfer method | # | Direct drive | |

| Feed | Three-axis cutting feed | mm/min | 1-10000 |

| Three-axis rapid feed | m/min | 48/48/48 | |

| Precision | Positioning precision | mm | 0.008/0.005/0.005 |

| Repeatability | mm | 0.005/0.003/0.003 | |

| Tool changing system | Number of tools | pcs | 21 |

| Max tool weight | kg | 3 | |

| Max tool length | mm | 250 | |

| Tool diameter (full tool/neighbor empty tool) | mm | 100/140 | |

| Tool magazine form | # | Jaw type (servo) | |

| CNC system | Control system | # | FANUC 0I-MF Plus |

| Spindle motor power | kw | 3.7/13 | |

| Three-axis motor power | kw | 2.7/2.7/3.0 | |

| Others | Required air pressure | kgf/cm3 | 6 |

| Electricity demand | KVA | 20 | |

| Net weight | kg | / | |

| Dimensions(LxWxH) | mm | 2250x2810x2940 |